Service Diagnosis is an important piece of the puzzle because a wrong diagnosis well may end up making the problem worst. Our experience gives a wide range of expertise in diagnosing the problem. CALL IRVING REFRIGERATOR REPAIR TODAY!

This article is an excerpt from the book called “Cheap and Easy” by “Douglas Emley”. Hope our readers find it very useful.

A Prime requisite on the initial contact is: Always allow the customer to explain the problem. Many times the trouble can be diagnosed more quickly, based on the conclusions until the full story has been evaluated. Then proceed with the diagnosis.

Before starting a test procedure, connect the refrigerator electrical service cord to the power source, through a wattmeter, combined with a voltmeter. Then make a visual inspection and an operational check of the refrigerator to determine the following:

- Is the refrigerator properly leveled?

- Is the refrigerator located for the proper dissipation of heat from the condenser? Check the recommended spacing from the rear wall and clearance above the cabinet.

- Feel the condenser. With the compressor in operation, the condenser should be hot, with a gradual reduction in temperature from the top to the bottom of the condenser.

- Are the door gaskets sealing properly?

- Does the door, refrigerator, or freezer, activate the light switch?

- Is the freezer compartment fan cover in place?

- Is the freezer compartment fan properly located on the motor shaft?

- Is the thermostat thermal element properly positioned?

- Observe the frost pattern on the evaporator.

- Check the thermostat knob setting.

- Check the air-damper control knob setting.

- Make a mark on the bracket opposite the slotted shaft of the defrost timer to determine if the timer advances.

- Are the air ducts free of obstructions?

The service technician should inquire as to the number of people in the family to determine the service load and daily door openings. In addition, the service technician should know the room temperature.

After this phase of diagnosis is completed, a thorough operational check should be made of the refrigerator system and any components not previously checked in the following order.

Freezer and refrigerator compartment air temperatures

The freezer and refrigerator compartment temperatures are affected by an improper door seal, frost accumulation on the evaporator, the service load, the ambient temperature, percentage of relative humidity, thermostat calibration (cut-in and cutout), the location of the freezer compartment fan blade on the motor shaft, and the compressor efficiency.

From this, it is evident that the temperatures are not always the same in every refrigerator, even under identical conditions.

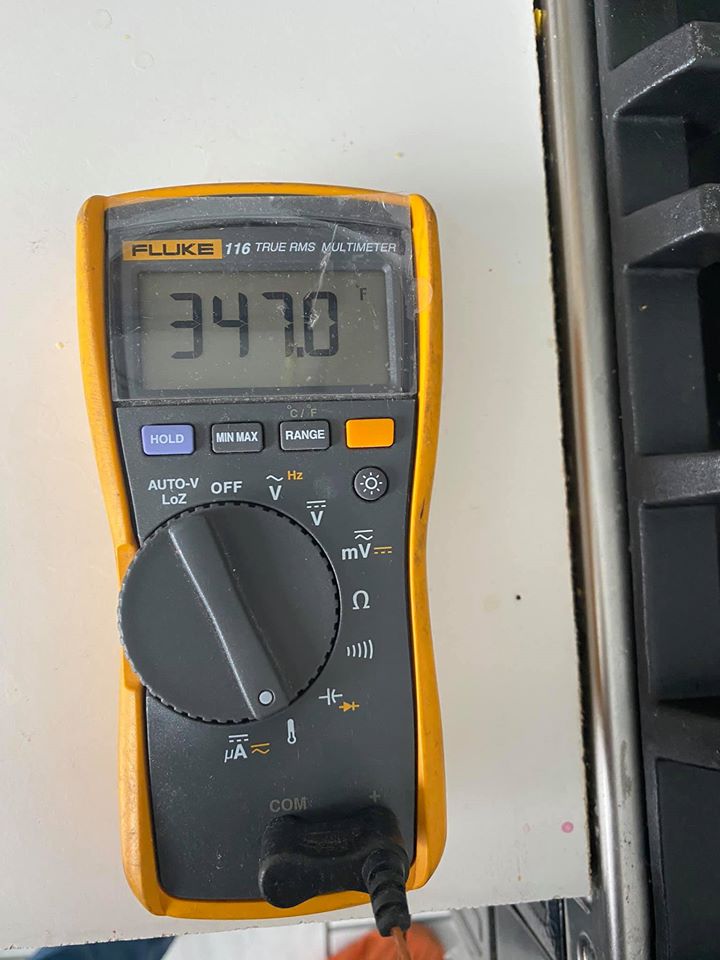

Line voltage

It is essential to know the line voltage at the refrigerator. A voltage reading should be taken at the instant the compressor starts, and also while the compressor is running. Line voltage fluctuation should not exceed ± 10 percent from the nominal rating. Low voltage will cause overheating of the compressor motor windings, resulting in compressor cycling on the thermal overload, or the compressor may fail to start.

Inadequate line wire size and overloaded lines are the most common reasons for low voltage at the refrigerator.

Continue reading about “Dryer repair symptoms“